Design Research

While visiting ‘Wijnkasteel Genoels-Elderen’, the northernmost wine castle of Europe, I had the opportunity to interview the owner of the company. He told me that his main concern for the quality of his wine were the conditions of the wine-cellar, where the ripening process was taking place. One of the most important aspects of the ripening process is that it should take place under a narrow range of temperatures. I suggested the conceptual development of temperature and humidity sensors made to fit to the side of a wine barrel, allowing for accurate grid-based monitoring of ripening conditions. And thus, June was born.

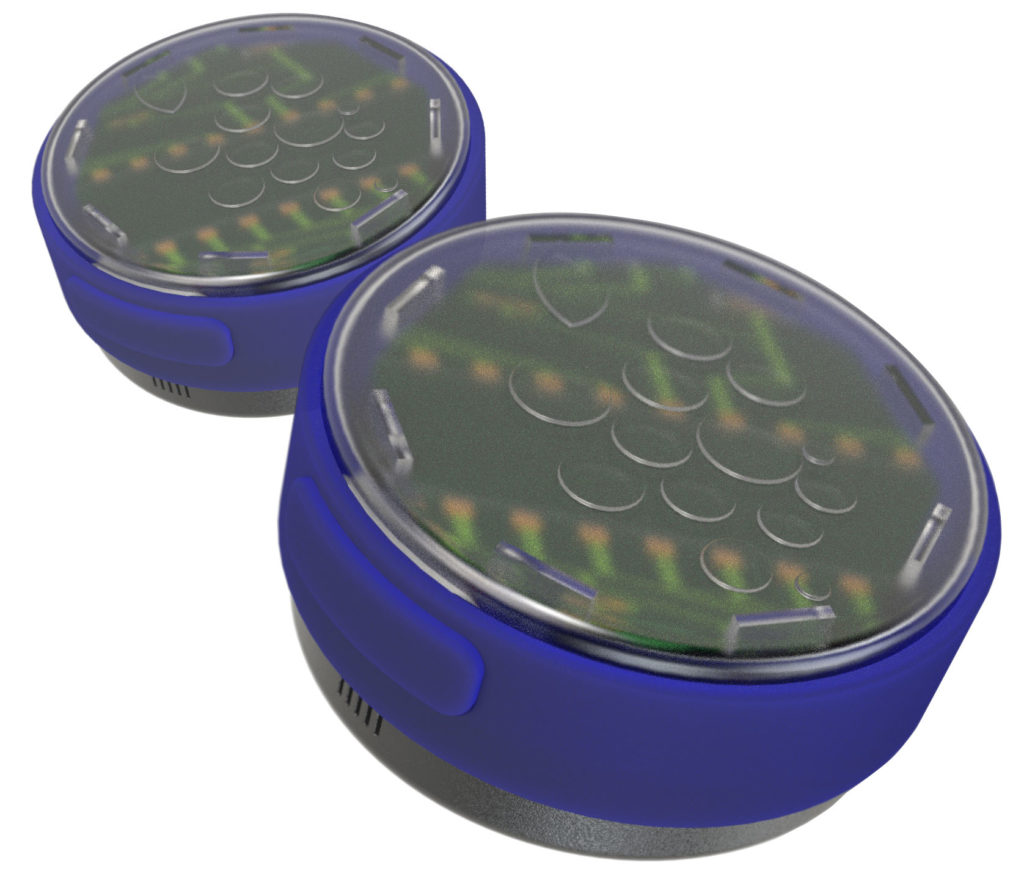

The June Pods

The June, temperature and humidity sensors are equipped with LoRa antennas, allowing for easy communication between modules. Connecting one pod to the internet allows for a constant flow of information between the network of pods, completely avoiding the need for elaborate network connections.

Interface Design

The June Interface

The June Interface was designed to serve as a digital feedback mechanism, optimized to keep track of and monitor all installed June sensors. In this concept, June owners can keep an eye on their indoor climate with a grid-based layout, connecting all June pods to a central hub. Only the central hub needs to be connected to the internet, while all other pods can communicate with the grid.

The June Exploded

Rubber Outer Ring

Injection molded silicone rubber ring for easy handling and better resistance against drops.

Translucent Top Shell

Injection molded translucent plastic with snap locks for PCB and embossed logo on top.

PCB

Custom PCB with LoRa antenna, rechargeable battery, temperature and humidity sensor and usb-c connector.

Plastic Bottom Shell

Injection molded black plastic with open vents for optimal air flow to temperature sensor and embossed holes for pressure fit of magnets.

Neodymium Magnets

Pre-fab magnets for strong hold on metal rings of wine barrels.